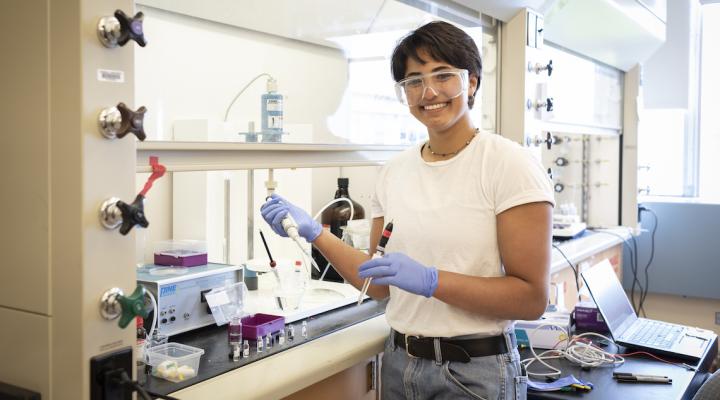

For her poster "Block Copolymer Membranes for Dynamically Responsive Material Systems" presented to Divya Srinivasan, at the ASEE St. Lawrence Section Annual Conference. Divya is an undergrad in the Wiesner Group.

Abstract

Nanofiltration membranes can be used in water treatment to remove hardness and pesticides from ground water. These membranes require low energy consumption, have high flux, and will retain viruses, bacteria, and suspended solids from wastewater treatment that can be used for further analysis and characterization. The approach in this project is to fabricate ultra- to nanofiltration membranes from block copolymers.

Block copolymer (BCP) derived membranes combine the narrow pore size distribution from track-etched membranes with the high pore density and high flux associated with phase inversion membranes for applications in filtration. The BCP used, in this project, is a triblock terpolymer: poly(isoprene-b-styrene-b-4-vinylpyridine) (PI-PS-P4VP or ISV). These isoporous membranes are produced by a hybrid BCP self-assembly process combined with non-solvent induced phase separation (S-NIPS). The resultant membrane is comprised of a uniformed, ordered, selective skin layer above a mesoporous, sponge-like support layer.

This project attempts to tune the size of these pores into nanopores so that the membranes can be used for nanofiltration. In order to tailor the pore size, the homopolymer polyacrylic acid (PAA) will be combined with our ISV polymer casting solution. These two polymers were expected to interact by hydrogen bonding inducing the formation of micelle complexes that aggregate into tighter morphologies with a smaller lattice parameter than a pure ISV polymer system, thereby producing smaller pore sized membranes.

Here, we demonstrate the successful replication and fabrication of ultrafiltration membranes from ISV by the SNIPS process under controlled casting conditions. With the additions of small amounts of PAA to the ISV polymer casting solution, the average pore size is reduced from ~23.3 nm to ~21.5 nm, however, the ordered top surface of the membrane is disrupted. Additionally, with the decrease in pore size, the distribution of pore sizes increases/widens making it no longer suitable for nanofiltration separation purposes. The decrease in pore size seen with the addition of PAA is not substantial enough to move from the ultrafiltration to nanofiltration regime.